Our Exoskeleton gets industrial support

- Matthew Dickinson

- Dec 4, 2021

- 3 min read

Updated: Dec 29, 2021

While at the first stages of the testing and development of our version one 3D printed exoskeleton, some larger questions were beginning to arise. For example, most Polylactic Acid (PLA) are a glucose baste thermoplastic, meaning they tend to be made from sugar elements thus, making them biodegradable. This raised huge questions that if we wanted to continue this work how we could move forward and still be able to offer this skeleton in this format. This is where thanks to the company 3DGribe we were introduced to a new company called Copper 3D. There new PLA boasted that their material was act far more successful when looking to lower bio-film collection, this is done by their impregnation of copper nano particles into the PLA. But it was brand new at the time and needed further study to ensure its examination to ensure it would operate ideally as a material for our application.

An Introduction

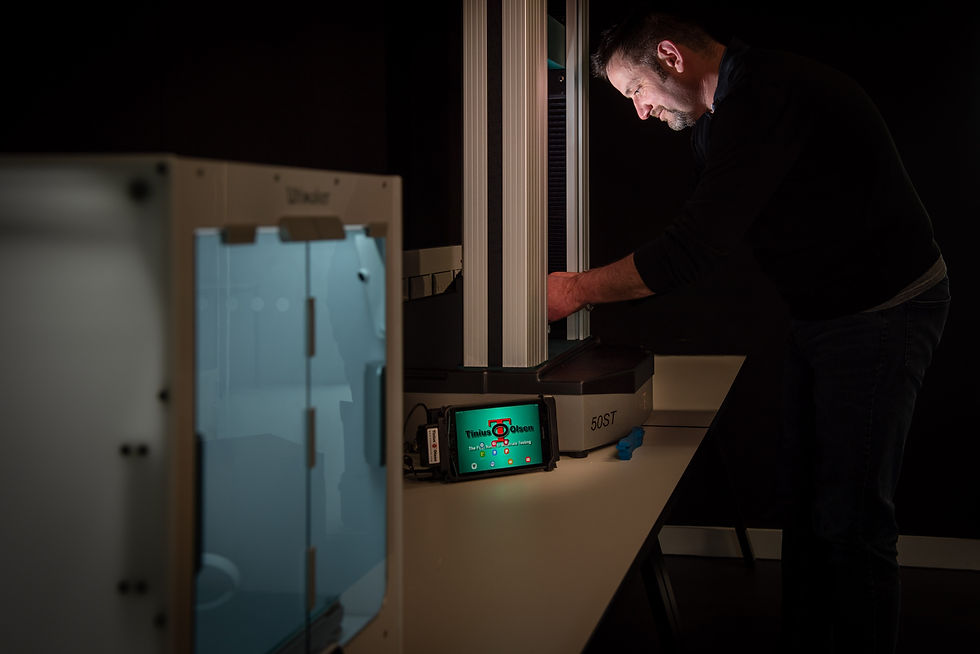

Without sounding to much of a cliche, after working lab late one night. The university of central Lancashire had some industrial visitors, who were interested in possible collaboration and at the time were having a tour of the university's new £35 million building the "Engineering innovation centre" (https://www.uclan.ac.uk/business/develop-your-business/engineering-innovation-centre) After the a short introduction to the project the company made themselves known as the international testing company "Tinius Olsen".

After a series of discussions they agreed to help us with a loan of equipment valuing over £60 thousand, they could see what we are trying to solve and offered to help.

The pandemic hits

Not to much longer after our agreement did the pandemic hit, stopping physical development the following 12 months of high restrictions would prove to be some of the most crucial in networking and meeting like minded developers from this field.

During this time our lives become quite virtual making the whole world much smaller than it once was. Just by chance a short meeting was organised to talk to the international technical director Shawn Byrd, about what the sim of the project was and where we would like to take this for the future. At the same meet, Shawn suggested that to get to knowing where the industry is headed he recommended that we joined the American Society of Testing and Materials (ASTM). As this technology was still very new, the ASTM had noted that this was a problem and have brought together over 100 specialists from all over the world to discuss not just ways to develop this equipment, but how to do this safely. Over the following months, we held numerous chats and talks about what we were trying to do.

Material Testing what we know

To establish a clear understanding about how the material (CopperActive PLA) behaviors the decision was taken to use of Tinius Olsen 50 ST and start with looking at 100% infill of a ASTM D683 type 2 dog bone. By establishing the Young modulus in all three components we would clearly understand orthotropic state of the material. As noted in the D683 eight samples where produced in both parallel to the 3D print stage and also perpendicular and then in this case all components could be tested, as one major problem with the use of fused disposition method (FDM) is called the inter-boundary layer. This occurs from the process of material being placed on top of itself, as the material is hot, it then has a small window to cool, this then makes a bond is weakened.

To ensure, validation of the work the computational computer package COMSOL mutiphyics was used.

As this work will be making up work for a journal article all results can not be discussed here. From testing on the machine and also used the 50 ST machine we have been able to establish an accurate digital model to inform. Through this testing we quickly realised that the PLA on its own would not be enough over a long period, following this we then forwarded our thinking into the use of PLA shells. This idea is simple the outside of the material is a shell and the core can be something else for example a PLA with a ABS core. Continuing from this we also began examining the idea that the way the lattice (core shape) is configured could help the material perform even better.

We have been able to establish a material that is both strong and displays an ideal elastic to support the body. This advancement could not have been done without the huge support from the company Tinius Olsen.

Comments